Heifeiling is committed to providing customers with the most effective graphite solutions to meet their most challenging needs. We can independently recommend the best and most economical graphite grade for your application.

When developing our own materials, Heifeiling cooperates closely with universities and research institutes. Heifeiling Graphite is constantly redefining boundaries through continuous testing, grade formulation and purification to develop innovative graphite material solutions for customers in more than 30 countries.

We can successfully complete challenging thin-walled machining jobs by optimizing fixtures and machining methods.

We prepare 3D models according to drawings and write programs to manufacture the required products. Upon request, we can also measure the actual product and produce the product to actual size.

We can perform special ID machining jobs to create solid parts without cutting the workpiece into segments.

Large rings, pipes, chimneys, pedestals and andands are made from smaller parts. This unique trapezoidal design eliminates the need for large diameter feeders that typically require long lead times.

We can perform complex machining tasks such as ensuring that there are no gaps between mating surfaces (no light leakage), which is required for segmented products used in compressor piston rings and similar applications.

We are capable of fast precision machining of very demanding porous objects.

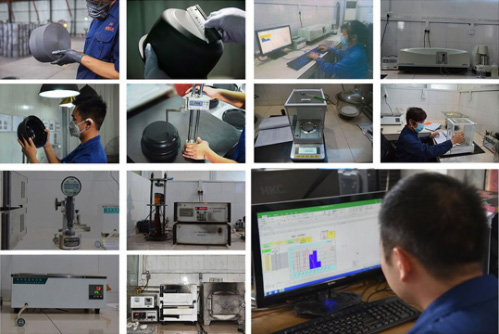

● Dimensional inspection: According to customer drawing requirements or national standard tolerance table

● Shore hardness testing

● Flexural strength test

● Quantity

● Filler

● Weight

● Component